Nerdy Post #3: What Is “Malt” And Why Is It Needed?

In this nerdy post, you will learn what “malt” it is all about – and why it plays such an important role in the production of whiskey. And as a bonus, I will also dig into why “malting” plays a big role in the flavor and taste profiles differences between American and Scotch whiskey.

For the longest time, I had no clue what “malt” was, what the process of “malting” barley was all about – and why it was relevant. In the process of finding out, another miracle of nature unveiled itself, as many times before, when you dig into the details about whiskey. The word “malt” is derived from “maltose”, which is basically two glucose molecules that are linked together. But more on that topic below.

So, let’s get started ….

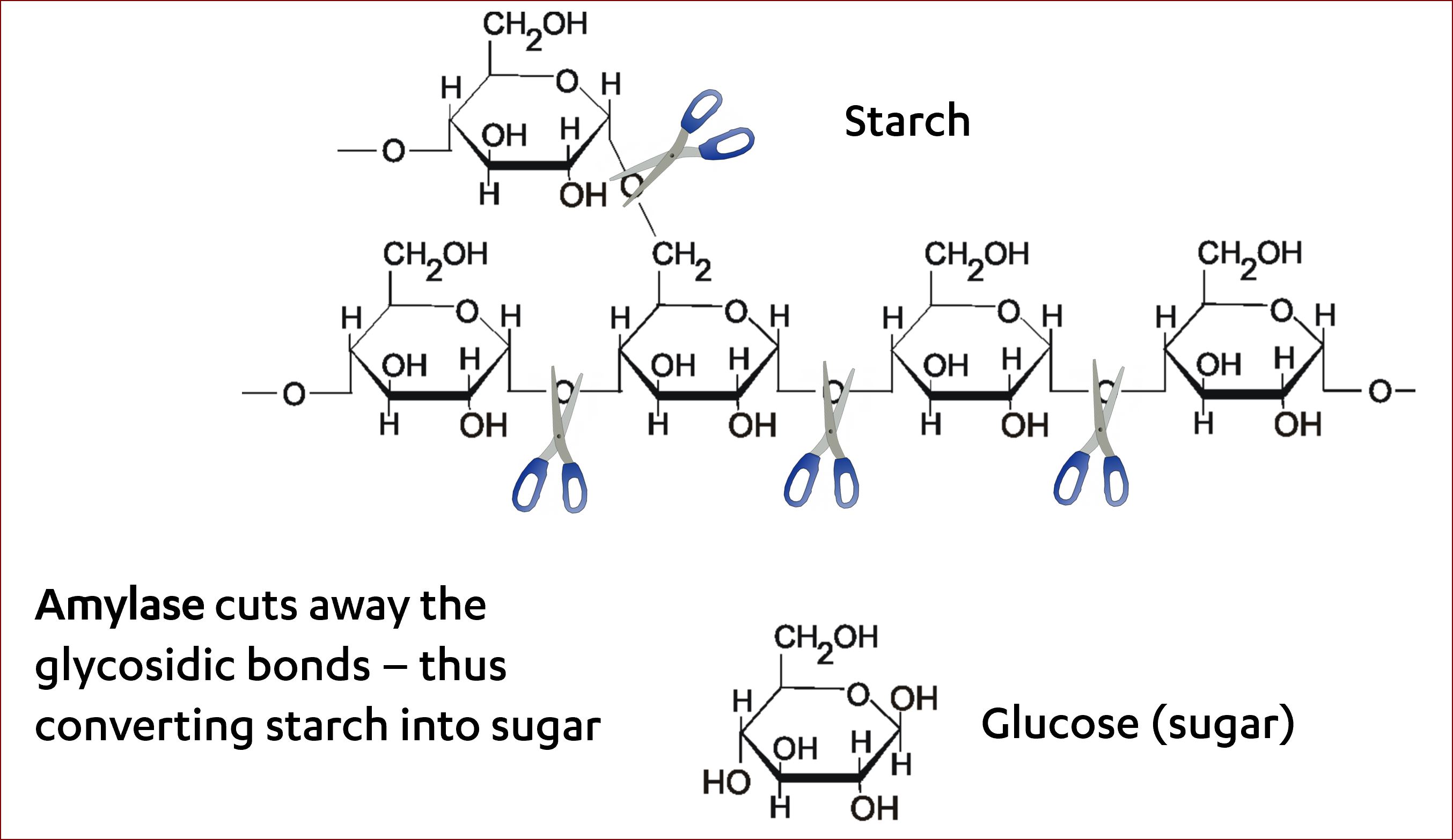

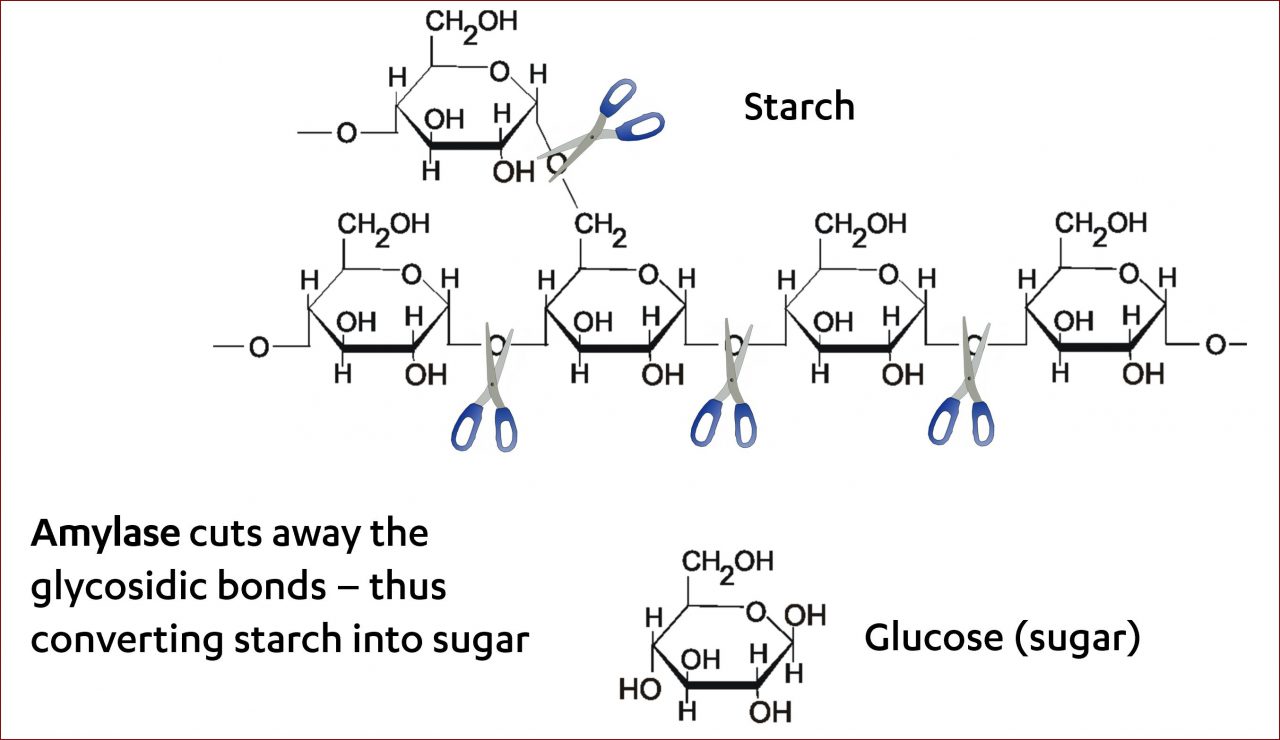

When the grains arrive at the distillery, they are crushed into what is called “meal”, which is a coarse flour. The grains are crushed to get to the starch inside them. Starch is a “polymeric carbohydrate” and before your eyes glaze over and you close the browser thinking “this is getting a little nerdy for me”, give me one second: “Polymeric” just means that the molecule in question (starch) contains multiple smaller molecules that are repeated. In starch, those smaller molecules are glucose (i.e. sugar).

Sugar is exactly what you need to get the fermentation going because this is what the yeast needs to produce alcohol. And that’s why we love those yeast cells so much – because they produce alcohol like there was no tomorrow. They basically piss alcohol and fart CO2 (excuse my French).

There is just one problem: Those repeated glucose molecules inside the starch are held together with a real tough glue called a “glycosidic bond”. Don’t worry about that name – just think of it as glue. Unfortunately, the yeast cells are unable to process the glucose with the glue active.

And this is where malt and malting come into the picture.

Malting simply means that you take some grains, put them into some water, wait until they start sprouting (a.k.a. germinating) – and then dry them again. In other words: Malted barley is just normal barley where a little sprout has come out, as you can see in the picture below:

So why on earth do you want to go through this process? It turns out that grains produce an enzyme called “amylase” when they sprout. Amylase has this amazing property that it destroys the aforementioned glue – effectively converting starch into glucose. And amylase is very effective; By adding just a few percentages of malted grains into the cooking process, it breaks downs the starch in mere hours:

Cool, right?? And once the glucose has been set free, you add the yeast – they do their thing – and we all hold hands and sing kumbaya.

So why barley – and not other grains?

Not many people know this, but you can malt almost all types of grains – including corn. Almost everybody uses barley, though, for three good reasons:

- The historic aspect. Depending on who you ask, whiskey production started in either Scotland or Ireland (or maybe another place – who knows), and they have been using barley for the longest time. As you can imagine, the American settlers back in the day (that started distilling) came from those countries. (DISCLAIMER: The are extremely few written records from that time, so exactly who did what with whom – as well as where and when – is unclear).

- Production reasons. Barley is easy to handle, easy to dry and produces a great yield of the enzyme amylase.

- The flavor profile. Malted barley produces a flavor profile that many people find very agreeable and mating other grains produces a distillate that sort of lack this flavor profile.

So pretty strong reasons right there, but as I mentioned, other grains can be used. When you do see that, it primarily malted rye.

Are there alternatives?

Yes. You can use industrial enzymes that do what amylase does, and while it may sound quite nasty, it is not a problem at all from a health or quality perspectives; The industrial enzymes evaporate when the heat gets to a certain level and leaves no residue behind.

There are a lot of manufacturers that use industrial enzymes and they even use them together with malted grains to ensure quality and persistence in the production process.

What about “single malt” – is that whiskey made from just one type of malt?

That would be logical, given the name – but that’s not really what a single malt is. In this context, the word “single” refers to the whiskey being made at a single distillery. Single malt is almost synonymous with Scotland, but there are phenomenal single malts made several places in the world – including in the US.

And on the topics of Scotland … you mentioned something about the different flavor profiles?

Exactly – and this is where it gets interesting. You probably know that Scotch and Bourbon tastes VERY differently, even though they are both whiskeys that have gone through a similar(ish) production process and have been aged in wood barrels. There are two reasons, really, and they are both related to malt:

- In Scotland, nearly everyone uses 100% malted barley. As I explained earlier, malted barley has a very distinct flavor profile and when you use 100% malted barley – that profile becomes VERY different from e.g. a Bourbon, where there is often less than 10% malted barley.

- The second reason is linked to the malting process itself. When the barley starts to sprout, you need to dry the grains again, as I described in the beginning. In the US, the drying process is done using hot air (just like a giant hairdryer), whereas they (often) use hot smoke to dry the grains in Scotland. That smoke comes from dry peat that is harvested from the grounds in Scotland. Peat is basically decayed vegetation and when you burn peat, it REALLY smells smoky. That’s why the malted barley absorbs a lot of this smoke, so that it, in turn, can release that smoke into the whiskey. So, when whiskey is “peated”, it means that it is smoky – and that it comes from the malted barley.

And just like you can get single malts from around the world, you can also get peated whiskeys from around the world.

Well, that’s enough for this post. If you enjoyed it, please follow me on Instagram via my profile @the_bourbon_nerd. If you have comments, correction or ideas for another nerdy post and please send me a message on Instagram or here on Bourbonr.com.

About me:

My name is Henrik Brandt and I’m based in Copenhagen, Denmark. I’m madly in love with the US and have visited 49 stated (only Alaska remains). American whiskey is my big passion and I will be publishing my first book on the topic in November. Besides nerdy posts on Bourbonr.com, I write whiskey reviews on straightwhiskey.dk (It is in Danish – so don’t bother to visit. Danish is a weird language that is more like a trade barrier, than anything else). My day-job is in the dental business, there I specialize in digital orthodontics (yup, that’s a thing).

18 comments

Very informative read. Thanks for the information!

You are welcome!

As a retired general dentist I was pleasantly surprised to learn that a professional colleague such as yourself is demonstrating such a well-read interest in a subject so unrelated to his “day job.” (And in so relished a topic as well!) Keep up the great work and I will look forward to subsequent posts.

Thank you and good to know, that there is someone else from the dental world in here!

This is the most concise description of malting and the science behind it that I’ve ever read. When people ask me what a single malt is I’m just gonna link them to this post. Thanks!

Wow – thanks!

Very informative! I wondered how peet was used in making scotch. Now I know. Much Thanks! Ag

You are welcome!

Barley is also the main ingredient in making beer (other than water)

This is awesome. Interesting, informative and entertaining. I will be on the lookout for your book.

Thank you!

Well written! You may be Danish but you excel in English!

Coming from a brewing background into whisky, I already knew about amylase since it’s also integral to beer, but I’ve always been surprised at how little even extreme whisky lovers know about the production of the object of their affections! Well written informative post! Thank you!

Wow – thanks!

I like how you answer both the how and the why of using malted grains. Can you provide some insight as to why the grains need to be dried again after sprouting?

It’s to halt the germination process, which is what the seed wants the enzymes for in the first place. By drying the grain at the right temperature, you kill the seed without destroying the enzymes. That makes the malt pretty stable, stored properly it will last a year or more easily.

Thanks Henrik. Very informative indeed. Amused by your profession too ! Maybe we might hear about Digital Malt too in future ?